How to Restore Seized Engine: Causes and Procedures to Fix

A damaged timing belt, lack of lubrication, or extreme heat can all lead to an engine seizure. Over time, these problems will cause your engine to stop working, and you’ll need the help of a trained mechanic to get it going again.

There are several potential causes of engine seizures. Lack of oil, poor circulation, infrequent usage like not using the engine for a long time, being stuck in a hydro lock or vapor lock, and many more factors can lead to this.

In addition, the common belief is that once an engine has seized because of a lack of oil, there is nothing that can be done to fix it. It simply isn’t so. Using the proper method, you may cure the engine that has become seized. Unfreezing a frozen engine due to a lack of oil may be done quickly and easily.

How to Unseize an Engine?

If your engine has locked up because of a lack of oil, because the cylinder walls have rusted, or for any other reason, read on for an easy fix that will work immediately.

Engine Seizure Due to Rusted Cylinder Walls:

Even if the cylinder walls of your engine have corroded to the point that the engine has seized, you can restart it yourself. Engines seize because the rusting process inside the cylinders continues unabated. Since this corrosion happens when a car sits still for a long time, it lets the lubricant on the cylinder walls weaken and run off because of gravity.

The intake valves on some of the cylinders are always left open when a car is turned off. Condensation forms on the cylinder walls, piston surface, and rings when humid outside air is sucked into the engine and moves all the way to the cylinder head.

When left for too long, moisture can turn into rust, which can freeze the pistons in place and lock up the engine. If corroded cylinder walls are thought to be the problem, the steps below can be used to unfreeze the engine.

Step 1: Unplug Any Peripherals

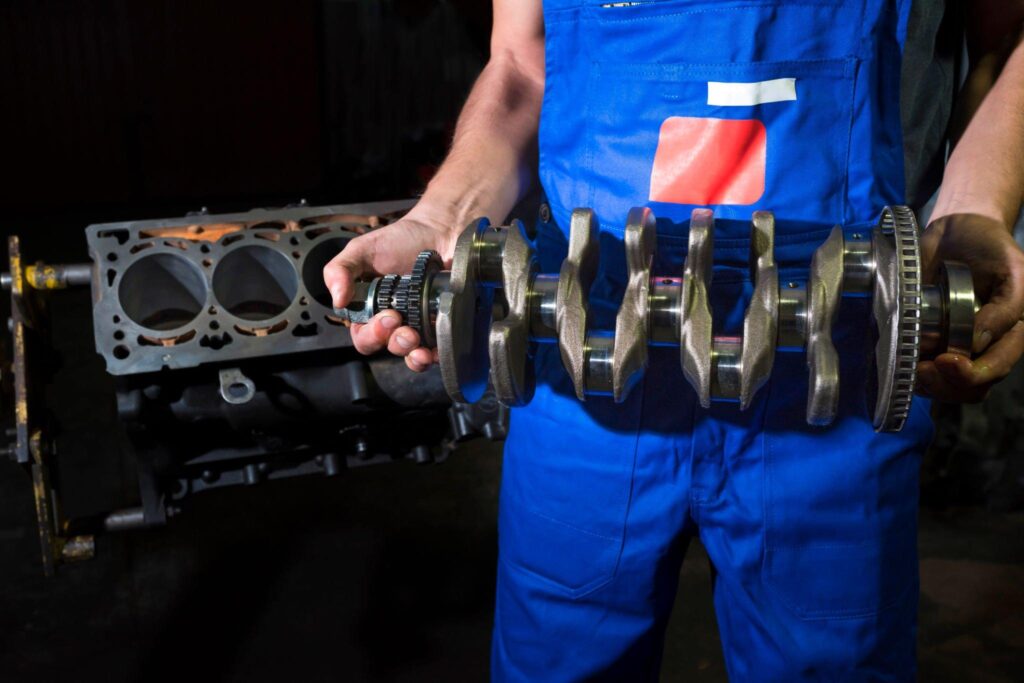

Many components outside of the engine block are powered by the crankshaft. Turn off the engine and remove any belt-driven components. Components like the alternator, water pump, and power steering pump all add friction to the crankshaft and decrease its efficiency. By taking them off, it takes less work to move the pistons and free the crankshaft so it can turn.

Step 2: Pressure-Level Adjustment

Take out the spark plugs with a socket and carefully unplug each wire, marking the order as you go. When putting it back together, make sure to connect each wire to the right cylinder so the timing stays right. As you try to loosen the pistons, it will be easier if you first remove the spark plugs to relieve any pressure in the engine that might be pushing against you.

Step 3: Remove the Valve Covers

Loosen the retaining nuts on each cylinder head with a wrench to take off the valve cover. The rocker arms may be seen more clearly if their coverings are taken off. Following this, loosen the nut on each rocker’s arm and pull them out. The exposed push rods must be removed from the cylinder head. This also makes it easier to turn the crankshaft without having to work as hard.

Step 4: Rotate the Crankshaft

Track down the front edge of the engine block. This will be located on one side or the other of a transverse engine. There is a pulley and belt setup up front, with either a circular harmonic balancer or the belt itself doing the driving. A bolt head will always be in the middle of the nut. Put a socket on the end of a long breaker bar and use it to loosen this bolt.

You may get the engine loose by turning the bolt in a clockwise manner. The engine may be unable to spin because penetrating oil has not been applied to the cylinder walls via the spark plug wells. Let the motor oil soak in for a few hours so it can get through the piston rings. Multiple applications over multiple days may be necessary for this procedure.

Those with manual transmissions can use the car’s momentum to turn the engine by rocking it back and forth while in gear.

Step 5: Assembly

After the engine is unbolted, you can put it back together the way you took it apart, making sure to replace any gaskets or seals you broke. First, check the battery’s charge, and then attempt to turn over the engine.

If the engine won’t turn over, the problem might be more serious than rusty cylinders, and you’ll have to decide if it’s worth doing an overhaul to try to salvage the car.

Tools Needed for Engine Repair:

- Socket sets,

- Screwdrivers (Phillips and standard), and

- Screwdrivers (Phillips and standard)

are some of the tools needed to remove the engine’s cylinder walls from their rusty shackles. Gasket sealant, masking tape, a pen, penetrating oil, and spare gaskets are all useful tools for this job.

Engine Seizure Due to Lack of Oil:

Lack of oil is another common cause of engine seizures. There are easy solutions to this problem. Here’s how it all works:

Method for Releasing Engine Blockage Caused by a Lack of Oil:

The process explained below can be used for fixing seized engines due to a lack of oil.

Step 1: Break up into Pieces

If the oil doesn’t penetrate, take apart the cylinder head and crankshaft. Smaller engines facilitate this process more. When dealing with a number of interconnected tubes, it is necessary to examine each one individually. If you haven’t figured out what’s wrong, take off the lid and investigate. Remove the cover of the mislabeled cylinder and turn the crankshaft. Now, see if you can bang the piston loose.

Wood can be used to ensure the status quo is maintained. Be sure the disc can slide along the cylinder’s base without damaging the crankshaft. You need to be cautious since your maintenance advice won’t help if something goes wrong. How to free a stuck piston is the first thing that springs to mind when contemplating restoring operation to an engine that has run out of oil. If this doesn’t get the piston moving, it’s time to call in the pros.

Step 2: Evaluate the Loss

When an engine seizes, there’s no way around the fact that both the cylinder and piston are broken. The ring may have been damaged or shattered because it became jammed. The piston ring needs inspection. If it turns out to be fine, you can try rotating it in the piston groove.

The oil lubrication will help the wedged rings recover from their condition. If necessary, you should change the rings. Pistons may become misshapen if an oil shortage causes the engine to seize. In the right light, you can clean it like new. If it’s damaged in any way, such as being ripped or cracked, it’s best to get it fixed by professionals.

Step 3: Inspect the Base

The bearings in the wrist pins and connecting rods should be checked regularly. If your wrist pins are making a banging noise, they are probably worn out. Connecting rods should be laid out on a flat surface so that wrapping can be checked. Make sure you know which way the bevels point before attempting to attach the new rings. It’s important to get the spacing right.

After the pistons have been properly fitted into the cylinder, clean engine lubricant should be applied to the cylinder and the piston. You may force the ring into the groove using a compressor. Reassemble everything and give the engine a whirl. This time, it’ll be on the loose. Those piston rings are really sharp, so be careful. Make sure you protect your hands by always using gloves.

Conclusion

That’s how easy it is to get an engine going again. Also, all this can be stopped from happening if you change your oil as often as the manufacturer tells you to. And if you notice any changes in the engine’s sound or performance, pulling over immediately is better for the engine. The symptoms mentioned above can help to determine whether the engine is seized or not.

If you notice a problem with your vehicle that cannot be solved by the procedure explained above, it’s best to have it checked out by a mechanic.

Frequently Asked Questions

What is the repair cost of a locked engine?

A seized engine is one that has become damaged or has run out of oil and hence cannot be started. Given the wide variety of possible causes, estimating the total price is challenging. The steps outlined here, however, will help you save money. This method is simple and effective for unlocking a stuck engine.

How to check if the engine is seized or not?

A few basic symptoms of the seized engine include: starting the engine is impossible; when the engine is being started, a single, loud clunk is audible as the pinion gear of the starting motor engages the flywheel in an effort to turn the crankshaft. These show that the engine is seized, and it can be fixed by following the procedure explained above.

How to unseize a small engine?

In order to free a small engine that has been stuck, follow these steps: Locate the spark plug and pull it out. Use some cleanser to scrub the furnace. The head must be opened and the piston cylinders softly tapped. Lastly, start the engine and look for signs of a seized motor after checking the motor and oil. If the symptoms return, try the treatment again or see a doctor.